SPRAYMASTER.TR.RR

Spray washing systems with rotating table for cleaning and deburring mechanical parts. Low production for medium/large parts

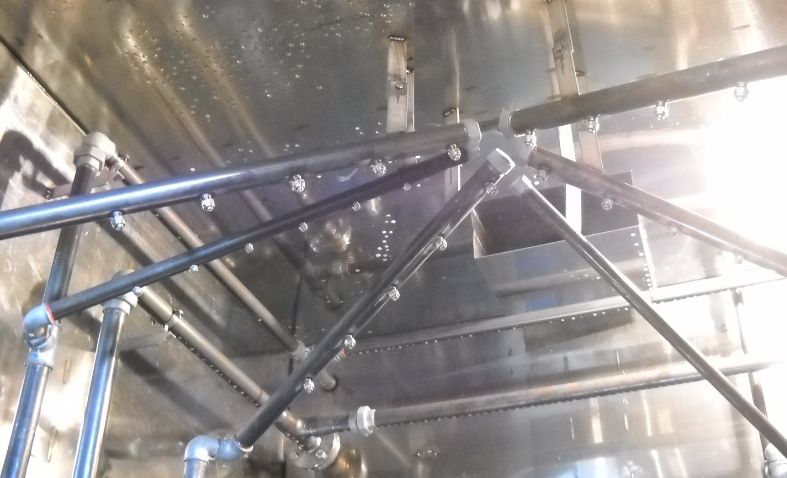

The SPRAYMASTER.TR.RR series industrial spray washing systems are designed to ensure maximum precision in cleaning mechanical parts, even in the presence of hanging burrs. These washing systems incorporate a rotating table that allows the component to rotate on its axis, optimising the effectiveness of the wash.

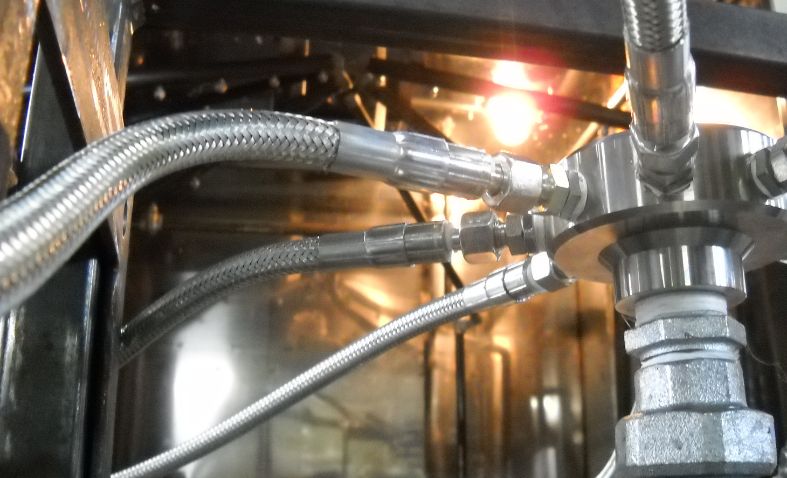

In addition to rotation, SPRAYMASTER.TR.RR systems are equipped with an additional washing device, available in a linear version or with a six-axis anthropomorphic robot, which allows for complete and uniform treatment. In the robotic configuration, the system achieves 7-axis management: the 6 axes of the robot plus the rotating table for rotating the piece, significantly improving the cleaning quality of mechanical parts.

The advantages at a glance

Here are the advantages of using SPRAYMASTER.TR.RR series systems.

Highly accurate cleaning

Ideal for cleaning complex mechanical parts and effectively removing hanging burrs.

Combined movement for thorough cleaning

It combines the turntable with an additional washing device, ensuring total coverage.

7-axis technology

The combination of 6-axis robots and workpiece rotation allows for extremely precise and customised treatments.

Suitable for complex machining operations

Designed to handle high-precision applications and mechanical deburring processes.

Advanced automation

It reduces the need for manual intervention, optimising time and costs in the industrial cleaning process.

Are you interested?

Request information on this or other washing solutions. Our consultants are at your disposal.