TANK.US

Industrial immersion washing systems with ultrasonic technology. Low production volumes

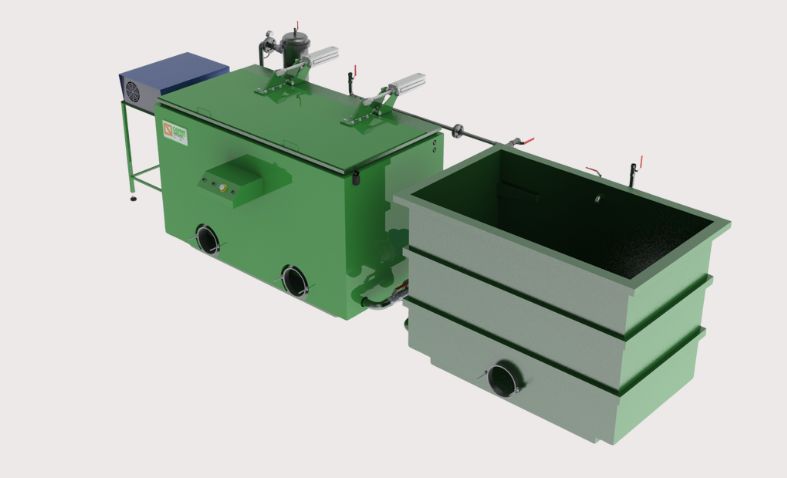

The TANK.US series of industrial tank washing systems consists of advanced washing tanks equipped with one or more immersed ultrasonic transducers and an autonomous generator, either internal or external.

The operation of TANK.US industrial tank washing systems is based on the diffusion of variable frequency vibrations in the treatment liquid. These vibrations generate pressure and vacuum waves that induce cavitation in the liquid.

Cavitation produces vapour bubbles which, when they implode, generate thousands of tiny impacts on the surfaces of the treated components, effectively helping to remove dry dirt and stubborn impurities.

The tanks are made of double-walled stainless steel with thermal insulation, ensuring durability, energy efficiency and thermal protection.

In addition, TANK.US industrial tank washing systems can be customised with various optional extras on request to suit specific production requirements.

The advantages at a glance

Here are the advantages of using TANK.US series systems.

Deep and precise cleaning

Deep and precise cleaning thanks to ultrasonic technology that effectively removes dry dirt and obstinate impurities.

High energy efficiency

High energy efficiency guaranteed by thermal insulation and double-walled stainless steel construction.

Durability and robustness

Durability and robustness thanks to the high-quality materials used for the tanks.

Operational flexibility

Operational flexibility with variable frequency ultrasonic transducers and internal or external generator.

Customised solutions

Customisation through specific options to adapt to different production requirements.

Are you interested?

Request information on this or other washing solutions. Our consultants are at your disposal.