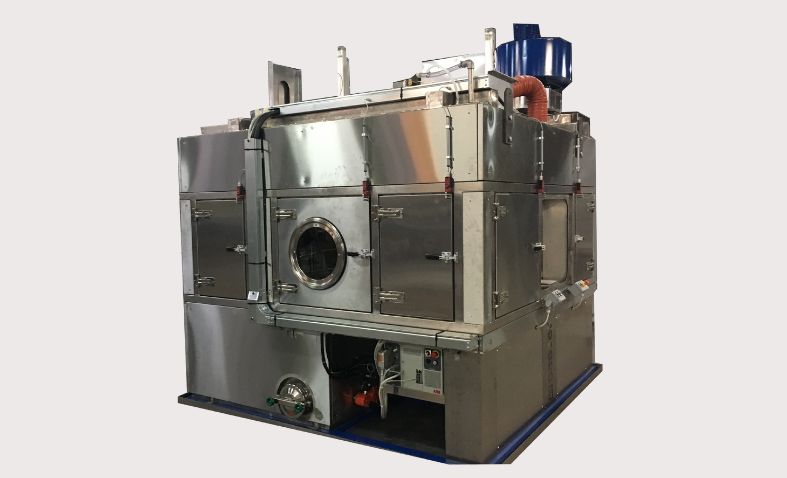

TUNNEL.CIRCON

Industrial tunnel washing systems with circular conveyor. High production volumes

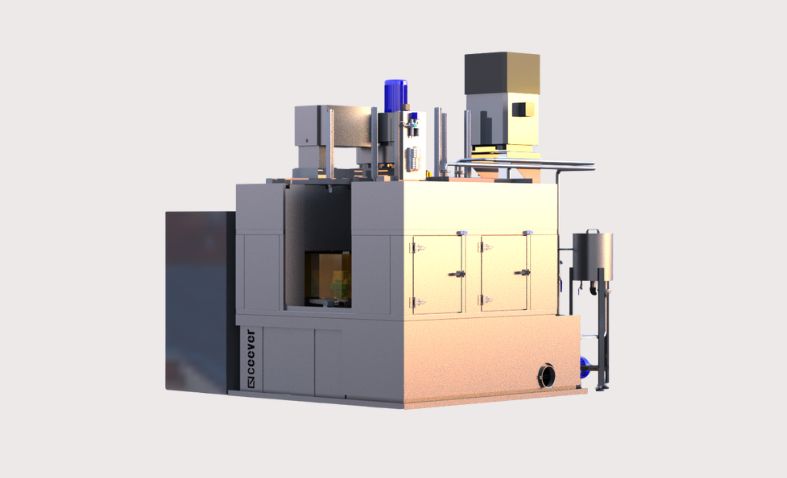

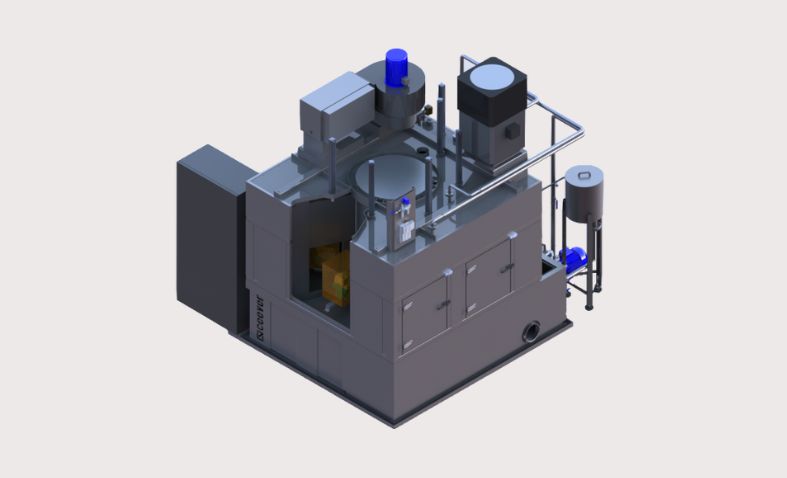

The TUNNEL.CIRCON series of industrial tunnel washing systems, equipped with a circular conveyor, are ideal for spray treatment of small and medium-sized mechanical parts. The transport system is based on a rotating table which, rotating around a central pivot, carries the part-holding satellites through the various processing stages, ensuring a continuous and organized flow.

The platform movement can be continuous or step-by-step; in step mode, the machine guarantees extremely precise positioning of the parts, enabling highly targeted, positional washing. In addition, the workpiece carriers can be rotated to optimize the effectiveness of the treatment.

Thanks to the unified loading and unloading position, part handling operations are simplified and can be managed by a single operator. This feature makes TUNNEL.CIRCON industrial tunnel washing systems particularly suitable for integration into island-type production lines, where space and efficiency are key.

The advantages at a glance

Here are the advantages of using TUNNEL.CIRCON series systems.

Efficient processing of small and medium-sized parts

Ideal for spray washing mechanical components of various sizes.

Circular transport system with rotary table

It guarantees a continuous and organized flow of parts through the various treatment stages.

Precise positioning with step movement

It allows for targeted washing, improving the quality of the treatment.

Rotation of the tool-holding satellites

Optimizes washing effectiveness thanks to the rotary movement of the parts during the process.

Simplified loading and unloading in a single location

It allows operations to be managed by a single operator and facilitates integration into stand-alone production lines.

Are you interested?

Request information on this or other washing solutions. Our consultants are at your disposal.