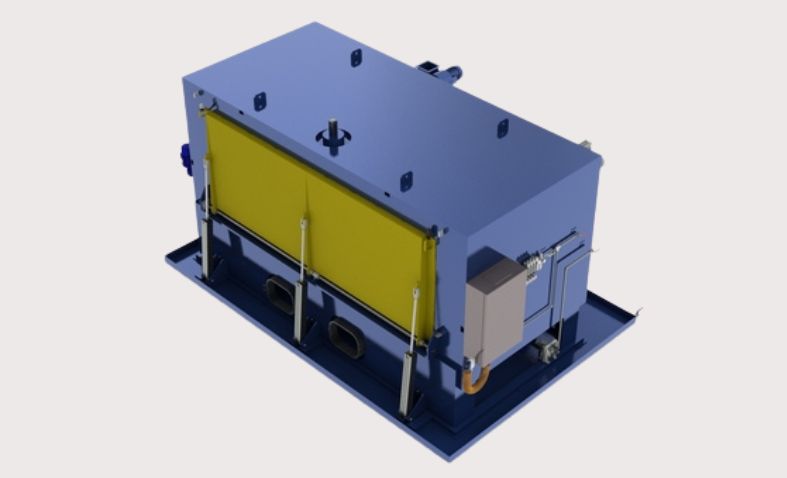

SPRAYMASTER.FX

Industrial spray and immersion washing systems for the complete cleaning of mechanical parts. Low production for medium/large parts

This innovative industrial spray washing system with integrated immersion washing is designed to offer maximum effectiveness in cleaning mechanical parts. The machine is equipped with a single chamber in which bath treatment and spray washing can be performed simultaneously, ensuring optimal results even for components with complex geometries.

The strategically positioned spray ramps generate strong turbulence with high-power underflow flushing. This system ensures total coverage of the surfaces of the parts, improving the cleaning quality of mechanical parts even in hard-to-reach areas.

The system operates fully automatically and is equipped with a special oil separator, which improves cycle efficiency and extends the life of the bath. Furthermore, thanks to its design, it requires low pumping and heating power, contributing to energy savings.

The advantages at a glance

Here are the advantages of using SPRAYMASTER.FX series systems.

Complete and uniform cleaning

Combines spray washing with immersion treatment to ensure effective cleaning even in the most difficult areas of mechanical parts.

High cleaning power

The spray ramps create strong turbulence and underflow, ensuring optimal results with high efficiency.

Total automation

Automatic operation reduces the need for manual intervention, increasing productivity and consistency in the washing cycle.

Energy saving

Designed to operate at low pumping and heating power, reducing operating costs.

Easy maintenance

Tanks with inspection ports and removable metal filters facilitate cleaning and routine maintenance of the system.

Are you interested?

Request information on this or other washing solutions. Our consultants are at your disposal.