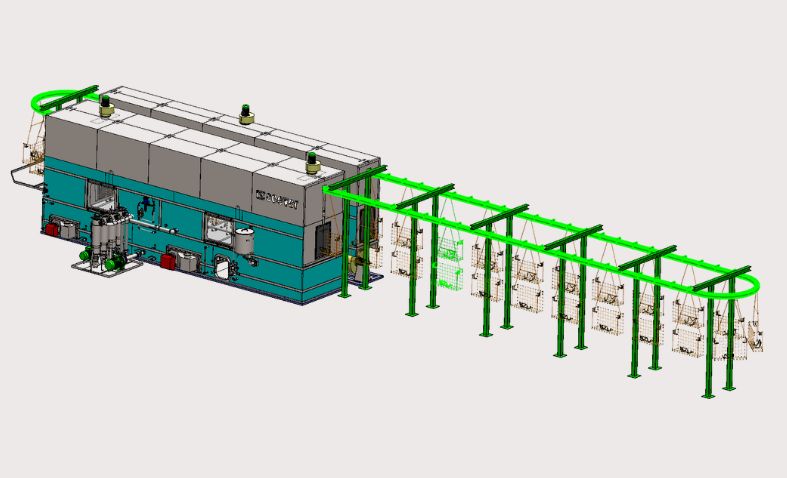

TUNNEL.AIR

Industrial tunnel washing systems with overhead conveyor. High production volumes

The TUNNEL.AIR series of industrial tunnel washing systems use an overhead conveyor to process items, which are loaded onto trays attached to a chain. Thanks to the closed-loop design of the conveyor, loading and unloading operations can be positioned either in separate stations or in a single concentrated area, offering great flexibility of management.

The conveyor can operate in continuous or step mode; the latter is particularly suitable for performing localized washing, ensuring precision and control during the cleaning process.

The advantages at a glance

Here are the advantages of using TUNNEL.AIR series systems.

Flexibility in loading/unloading positioning

Possibility of separate loading and unloading or concentrated in a single station, adapting to production requirements.

Closed-loop air transport system

It guarantees a continuous and safe flow of products during all stages of processing.

Continuous or step operating mode

Allows you to choose between a fluid or positioned movement, optimizing the washing cycles.

High-precision positioned washing

The step mode allows for precise handling of products at every stage of the process.

Suitable for treating complex items

Ideal for production lines that require thorough and customized washing processes.

Are you interested?

Request information on this or other washing solutions. Our consultants are at your disposal.