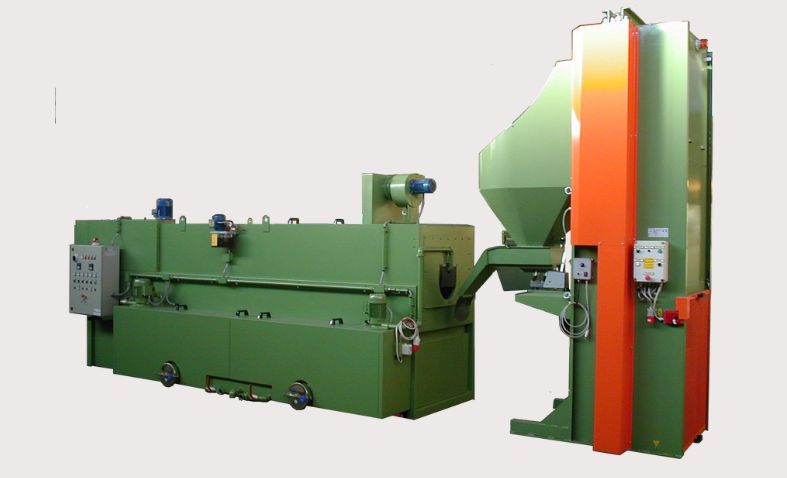

TUNNEL.DRM

Industrial tunnel washing systems for small metal parts and screws. High production volumes

The TUNNEL.DRM series industrial tunnel washing systems are industrial screw washers designed for the continuous and bulk treatment of small and medium-sized parts, such as screws, bolts, and small metal parts. Thanks to their configuration, they represent an effective and automatable solution for intensive cleaning processes in industrial settings.

The material feed system operates through the slow rotation of a cylinder equipped with a fixed pitch spiral, which moves the parts inside the plant. During this movement, the parts undergo various treatment cycles, including degreasing, chip removal, and drying. The continuous and controlled rotation of the spiral ensures relative movement between the parts, guaranteeing uniform and effective washing.

To meet specific production requirements, these industrial tunnel washing systems can be configured with optional extras on request, ideal for optimizing treatment cycles based on the materials and characteristics of the parts to be washed.

The advantages at a glance

Here are the advantages of using TUNNEL.DRM series systems.

Continuous and bulk processing

Ideal for washing large quantities of small and medium-sized parts such as screws, bolts, and small metal parts, without the need for individual positioning.

Delicate and effective handling

The controlled rotation of the fixed-pitch spiral auger ensures smooth feeding and uniform washing of the parts.

Complete treatment cycles

A single system can perform degreasing, chip removal, and drying operations, optimizing time and space.

Load automation

Automatic loading option to increase efficiency and reduce manual intervention.

Flexibility and customization

Optional extras available on request to adapt the system to specific production requirements and improve washing cycle performance.

Are you interested?

Request information on this or other washing solutions. Our consultants are at your disposal.