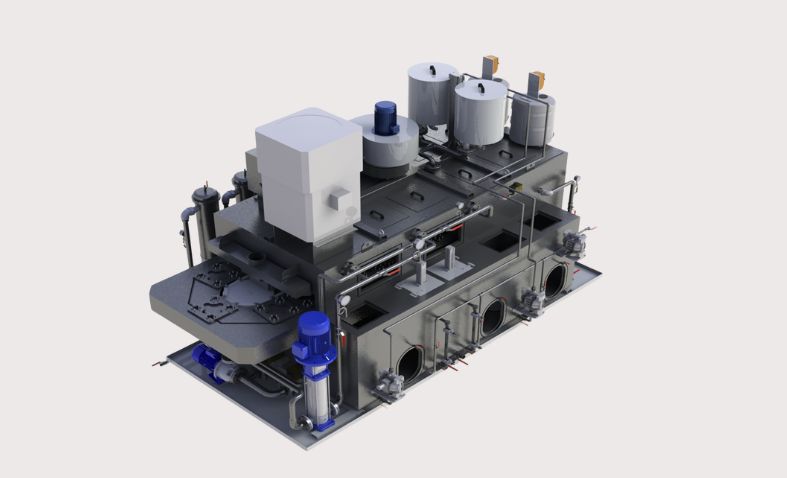

TUNNEL.RING

Industrial tunnel washing systems with ring conveyor. High production volumes

The TUNNEL.RING series of industrial tunnel washing systems are ideal for spray treatment of small and medium-sized mechanical parts. The rotating ring transport system moves the part-carrying satellites through the various treatment stages, ensuring a continuous and well-organized process.

The conveyor can operate in continuous or step mode, with the possibility of extremely precise positioning of components to perform localized washing when required. In addition, the workpiece carriers can rotate, improving the effectiveness of washing on all surfaces.

Inside the treatment chambers, the network of nozzles is designed to completely cover the surfaces of the parts, combining chemical, mechanical, and thermal actions for optimal results. If necessary, the system can be integrated with blowing and drying stages to complete the cleaning cycle.

During operation, TUNNEL.RING industrial tunnel washing systems guarantee a clean, odorless, and completely isolated working environment, ensuring safety and comfort for operators.

The advantages at a glance

Here are the advantages of using TUNNEL.RING series systems

Effective treatment of small and medium-sized parts

Ideal for spray washing on mechanical components of various sizes.

Rotating ring conveyor system

Ensures a continuous and organized flow of parts through the various stages of processing.

Continuous or step movement with precise positioning

Enables highly accurate washing positions for complex components.

Clean and isolated work environment

Odorless operation and completely separate from the production environment for greater safety and comfort.

Suitable for treating complex items

Ideal for production lines that require thorough and customized washing processes.

Interessato?

Richiedi informazioni su questa o altre soluzioni di lavaggio. I nostri consulenti sono a tua disposizione